Watch this short Fennell Spring Company overview!

Fennell Spring

Spring manufacturing that is responsive, reliable, and certified

Fennell Spring supplies precision springs and wire forms to industries worldwide that include automotive, firearms, commercial, industrial, government, aerospace, medical, and more.

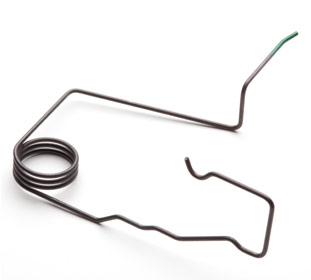

Operating from a 65,000 sq. ft. state-of-the-art manufacturing plant in Horseheads, NY, Fennell offers unbeatable floor-to-door turnaround time and prototype development. In addition to custom wire forms, Fennell offers a diverse variety of spring types including precision compression, extension, torsion, clutch, and conduit. Diameter capabilities range from .005″ to .3175″— all offered in a variety of raw and pre-plated materials to meet prototype and ongoing production needs.

PRODUCT CAPABILITIES

- Wire Diameter: .005″ to .3175″

- Length: Up to 275′

- Angular Tolerances/Bend Angle:

+/- 3 Degrees - Angular Tolerances/Free Angle:

+/- 10 Degrees - Linear Tolerance:

+/-0.5mm Radius: +/- 0.5mm

MATERIALS USED

- Alloys

- Brass & Bronze

- Music Wire

- Preplated Music Wire (Alumar, Gaitan, Bezinal)

- OTCS

- OTMB / Hard Drawn

- Shaped Material

- Stainless Steel

PRIMARY PROCESS CAPABILITIES

- 65 Coiling Centers

- lnline & batch stress relief

- Automated processes for efficiency

SECONDARY FINISHING OPERATIONS

- Grinding

- Keyence Vision System For Inspection

- 100% Inspection/Gauging

- Oil Dip For Rust Prevention

- Painting/Dyeing

- Shot Peening/Tumbling

- Special Packaging

MARKETS SERVED

- Aerospace

- Automotive

- Battery

- Power Generation

- Commercial/Industrial

- Computer

- Connector

- Electronics

- Defense/Firearms

- Military

- Marine

- Medical

- Lighting

- Semiconductor

- Valve

CONTACT

Fennell Spring

Fennell Spring Company

295 Hemlock Street

Horseheads, NY 14845

Certifications

ISO 9001

IATF 16949

ITAR Registered