Watch this short Marion Manufacturing overview!

Marion Manufacturing

A leader in progressive stamping, wire forms, and assemblies

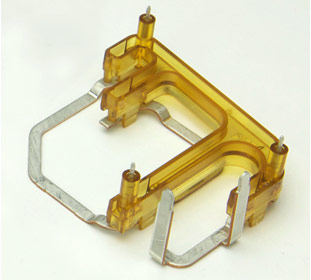

Marion Manufacturing is a leader in Progressive Die Stamping and also now offers CNC Machining. Established in 1946, Marion Manufacturing combines cutting-edge stamping and machining performance with value-added engineering consultation. Manufacturing all components in the USA at its Cheshire, CT plant, Marion creates simple to intricate parts through a forward-thinking approach that embraces new trends and technologies. By welcoming innovation, the company has reduced manufacturing costs, supported ecological green initiatives, and been recognized as a respected advocate for strengthening U.S manufacturing through employment diversity. (See article in The Hartford Business Journal.)

Marion’s production capabilities range from low-volume highly specialized custom components to high-volume commodity parts including four-slide stampings, wire forms, progressive eyelets, and assemblies.

Engineering & tooling

Marion’s in-house engineering group uses the latest 3D design software to develop tooling that is easy and efficient to maintain. The advantages of this in-house tooling control include maintained peak performance with optimum precision, continued readiness, and less downtime.

Marion’s engineering group can also partner with a customer’s research and design department to assist with the development of original parts for new applications— or improve existing applications and specifications to improve cost efficiency. Whether working independently or collaboratively, Marion’s engineering group ensures every specified part moves seamlessly and proficiently from prototyping and designing to precision progressive tooling for production.

Markets served

Marion services the aerospace, automotive, computer, connector, defense, electronics, hardware, firearms, food processing, medical, plumbing, power generation, semiconductor, superconductor, telecommunications, and wind energy and wind solar industries.

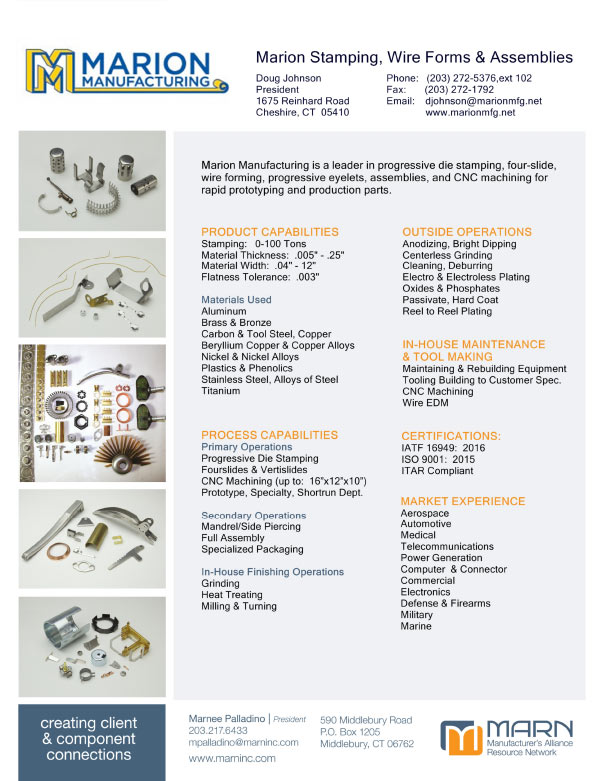

PRODUCT CAPABILITIES

- CNC Machining: 16″x12″x10″

- Stamping: 0-100 Tons

- Material Thickness: .005″ – .25″

- Material Width: .04″ – 12″

- Flatness Tolerance: .003″

MATERIALS USED

- Aluminum

- Brass & Bronze

- Carbon & Tool Steel

- Copper, Beryllium Copper & Copper Alloys

- Nickel & Nickel Alloys

- Plastics & Phenolics

- Stainless Steel

- Alloys of Steel

- Titanium

PROCESS CAPABILITIE

Primary Operations

- Progressive Die Stamping

- Fourslides & Vertislides

- CNC Machining

- Prototype, Specialty, Shortrun Dept.

Secondary Operations

- Mandrel/Side Piercing

- Full Assembly

- Specialized Packaging

In-House Finishing Operations Grinding

- Heat Treating

- Milling & Turning

OUTSIDE OPERATIONS

- Anodizing, Bright Dipping

- Centerless Grinding

- Cleaning, Deburring

- Electro & Electroless Plating

- Oxides & Phosphates

- Passivate, Hard Coat

- Reel to Reel Plating

IN-HOUSE MAINTENANCE

& TOOL MAKING

- Maintaining & Rebuilding Equipment

- Tooling Building to Customer Spec.

- CNC Machining

- Wire EDM

MARKETS

- Aerospace

- Automotive

- Medical

- Telecommunications

- Power Generation

- Computer & Connector

- Commercial

- Electronics

- Defense & Firearms

- Military

- Marine

CONTACT

Marion Manufacturing

(Fax: 203-272-1792)

Marion Manufacturing

1675 Reinhard Road,

Cheshire, CT 06410

Certifications

ISO 9001

IATF 16949

ITAR Compliant